Cleanroom Manufacturing at TN Plastics

At TN Plastics, we understand that purity and precision are critical for industries like medical devices, diagnostics, biotech, and advanced technology. Our Michigan facility features an FDA-registered, ISO 13485 certified, Class 8 cleanroom designed for the most demanding injection molding and assembly applications. This environment ensures that every component is produced under strict controls for airborne particles, humidity, and temperature, safeguarding product integrity from start to finish

Our FDA-registered cleanroom facilities (Class 6–8 compliant) and ISO 13485 certification ensure contamination-free production for medical-grade products. Whether you need components for medical diagnostics, fluid handling systems, or advanced technology applications, TN Plastics has the expertise to deliver consistent quality at scale.

Why Choose TN Plastics Cleanroom Manufacturing?

ISO Class 8 Cleanroom

Maintains stringent particulate and contamination controls, ideal for medical and high-tech plastic parts.

FDA-Registered & ISO 13485 Certified

Meets global standards for medical device manufacturing, ensuring quality and traceability for every lot.

Dedicated Workcells & Automation

Supports high-volume, consistent production for products like tubes, dishes, cartridges, and other plastic disposables.

Expertise in Material Selection

Extensive experience with FDA-compliant, high-performance plastics for specialized requirements.

Full-Service Support

Full-Service Support: From mold design and validation (IQ/OQ/PQ) to custom packaging and assembly, we deliver end-to-end solutions for OEMs.

Industries We Serve

Our contract injection molding services cater to a variety of industries:

Medical and Diagnostic Devices

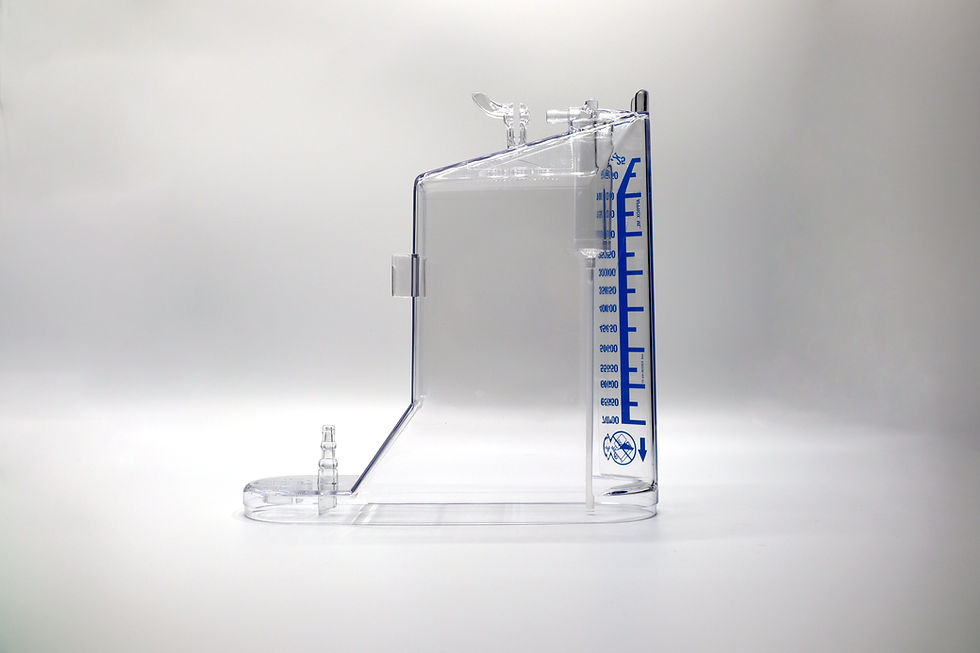

TN Plastics manufactures high-precision components for medical and diagnostic devices in its ISO Class 8 cleanroom. These include parts for point-of-care devices, diabetes management, cardiology equipment, blood filtration systems, and assay devices such as PCR testing units. The cleanroom environment ensures that components meet strict regulatory standards for sterility, traceability, and contamination control—critical for patient safety and device reliability

Labware and Bioscience Consumables

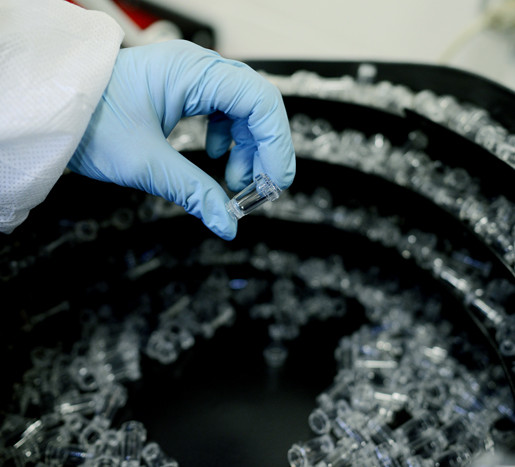

The cleanroom supports production of a wide range of labware and consumables used in bioscience and research, such as plastic tubes, petri dishes, specimen containers, and cartridges. These products require consistent quality, clarity, and chemical compatibility, and must be free from particulates or biological contaminants to ensure the integrity of scientific experiments and diagnostic procedures

Fluid Management and Microfluidic Components

TN Plastics specializes in components for fluid management and microfluidic systems, including valves, pumps, connectors, and micro-channels. These parts are used in medical devices, laboratory automation, and diagnostic platforms where precision molding and contamination-free production are essential for accurate fluid handling and measurement

Electronics and Robotics Requiring Ultra-Clean Production

For advanced electronics and robotics, TN Plastics produces plastic components that must be manufactured in ultra-clean environments to prevent dust, static, or particulate contamination. These parts are used in sensors, housings, and assemblies where even microscopic impurities could impact performance, reliability, or safety in sensitive applications

Your Partner for Quality and Reliability

With decades of experience and a proven track record of performance, TN Plastics is recognized as a top supplier to the world’s leading medical and technology companies. We combine best-in-class quality, responsive customer support, and scalable manufacturing to deliver the reliability your projects demand.

Ready to elevate your next project with cleanroom manufacturing? Contact TN Plastics to discuss how our controlled environment can help you achieve uncompromising quality and consistency.