CASE STUDY

Detailed Diagnostics

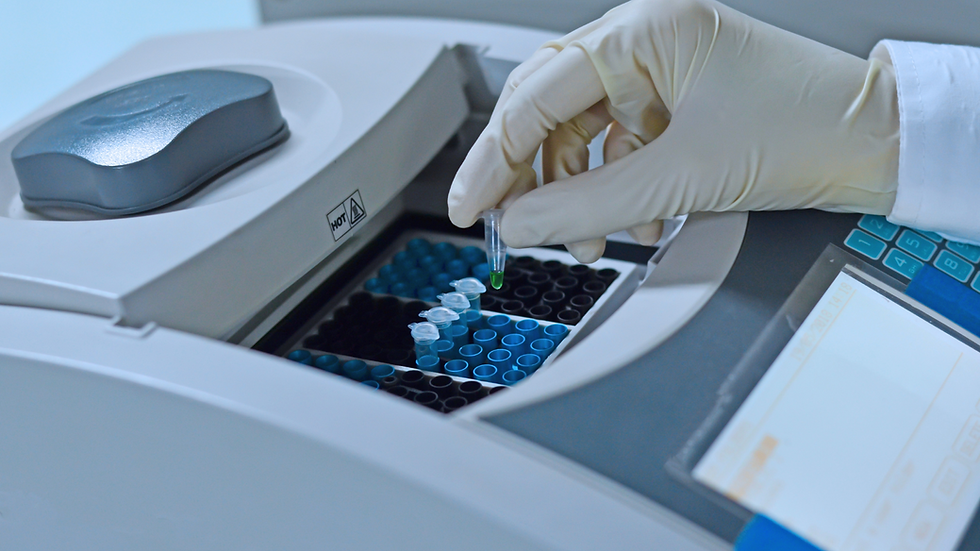

At TN Plastics, precision and innovation are at the heart of everything we do. In the healthcare industry, diagnostic accuracy is critical, and our expertise in precision plastic bead manufacturing has helped leading medical OEMs create reliable solutions for testing and diagnosis. This case study highlights how TN Plastics partnered with a medical device manufacturer to develop specialized beads for PCR testing, enabling accurate detection and diagnosis of infectious diseases.

The Challenge

A medical device manufacturer required a specialized bead capable of carrying a PCR reagent for detecting and diagnosing infectious diseases. The beads needed to meet strict requirements for chemical adherence, biocompatibility, and precision tolerances to ensure reliable test results. The challenge was to design a solution that not only met these technical specifications but also supported high-volume production without compromising quality.

The Solution

TN Plastics developed precision plastic beads with specialized surface finishes tailored to match the chemical adherence needs of PCR assays. Using advanced manufacturing processes and FDA-compliant materials, we delivered:

-

Specialized Surface Finishes: Designed to optimize chemical adherence for PCR reagents.

-

Biocompatible Materials: Ensured safety and reliability in medical-grade applications.

-

Precision Tolerances: Guaranteed consistent performance across high-volume production runs.

-

Scalable Manufacturing: Supported large-scale production to meet global demand.

By collaborating closely with the client, TN Plastics ensured that every bead met the stringent standards required for critical healthcare applications.

The Results

The implementation of TN Plastics’ solution delivered transformative outcomes:

-

Enhanced Diagnostic Accuracy: The specialized beads improved the reliability of PCR tests, enabling accurate detection of infectious diseases.

-

Global Adoption: TN Plastics’ beads are now used in leading diagnostic testing equipment worldwide.

-

Recognition for Quality: Our products are recognized as the highest quality among top medical OEMs.

-

Scalable Production: High-volume manufacturing capabilities ensured consistent supply to meet growing global demand.

These results strengthened the client’s reputation as a leader in diagnostic testing while supporting advancements in global healthcare.

KEY BENEFITS

Our precision plastic beads provide unmatched advantages for diagnostic applications, ensuring accuracy, reliability, and scalability in critical healthcare settings.

Chemical Adherence

Specialized surface finishes optimize reagent performance in diagnostic assays.

Biocompatibility

FDA-compliant materials ensure safety and reliability in medical-grade applications.

Precision Manufacturing

Tight tolerances guarantee consistent performance across all production runs.

Scalability

High-volume production capabilities support global demand without compromising quality.

Global Impact

Used in leading diagnostic equipment worldwide, our beads contribute to advancements in healthcare diagnostics.

Why TN Plastics?

TN Plastics combines decades of experience with cutting-edge technology to deliver exceptional results for healthcare manufacturers. Our commitment to precision engineering, scalable production, and customer satisfaction makes us a trusted partner for medical OEMs worldwide. Whether it’s developing specialized components or meeting high-volume demands, we deliver solutions that exceed expectations.