Medical & Diagnostic Devices

Precision Plastic Manufacturing for Healthcare Innovators

TN Plastics is a trusted partner for FDA-compliant injection molded components that power the next generation of medical and diagnostic devices. Our expertise in custom mold design, cleanroom manufacturing, and advanced automation ensures every part meets the most stringent industry standards for safety, reliability, and performance.

Medical Device Applications

Injection molded plastic components from TN Plastics are engineered to meet the demanding requirements of the healthcare industry. Our solutions address a wide spectrum of medical and diagnostic needs, ensuring precision, safety, and regulatory compliance at every stage.

Application Area | Example Components | Key Benefits |

|---|---|---|

Diagnostics & Lab Consumables | Microplates, pipette tips, test cartridges | Precision, sterility, cost efficiency |

Surgical Instruments | Forceps, retractors, instrument handles | Ergonomics, durability, biocompatibility |

Point-of-Care Testing | Housings, mixing chambers, fluidic chips | Rapid results, reliability |

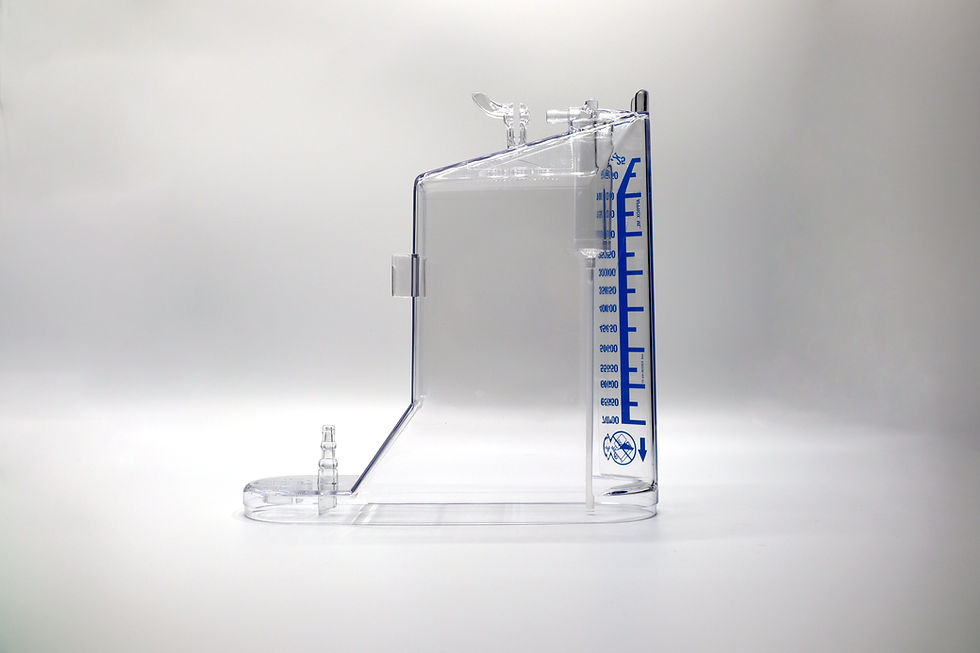

Fluid Handling & Delivery | IV connectors, valves, fluid reservoirs | Leak-proof, chemical resistance |

Microfluidics & Beads | Precision beads, micro-channels | Tight tolerances, custom materials |

Engineered to Perform

We combine advanced engineering with automation to accelerate innovation.

Custom mold design using 3D CAD simulations

Automated systems for repeatable, high-precision molding

27%

Flexible production volumes from prototyping to full scale

Whether you're searching for precision plastic manufacturing near me or a long-term contract injection molding partner, TN Plastics offers reliable, eco-conscious solutions tailored to your needs.

Applications in Medical & Diagnostics

Our injection molded plastic components are engineered to support a wide range of healthcare technologies.

Diagnostic cartridges and lab consumables

Microplates, pipette tips, reagent containers, and sample wells for accurate, reliable test results.

Point-of-care and home testing kits

Housings, mixing chambers, and fluidic channels designed for rapid diagnostics and patient safety.

Surgical tools and fluid handling systems

Forceps, retractors, instrument handles, and fluid delivery components that require precision and biocompatibility.

Microfluidic devices

Precision plastic beads and channels for advanced sample processing, mixing, and analysis.

Patient care and monitoring

Components for IV therapy, blood processing, respiratory devices, and more, all manufactured to strict medical standards.

Partner with TN Plastics

Whether you need a reliable supplier for high-volume production or a collaborative partner for custom medical device development, TN Plastics delivers precision, compliance, and innovation at every step. Contact us to discuss how we can support your next medical device breakthrough.

Why Choose Tn plastics for medical device manufacturing?

Cleanroom molding (Class 6–8)

Production in ISO Class 8 cleanrooms for contamination-free, sterile components suitable for critical medical applications.

ISO 13485 certified & FDA registered

Manufacturing in facilities that meet global regulatory requirements, ensuring full traceability and compliance.

Decades of experience

Serving top medical OEMs with a reputation for quality, consistency, and cost-effectiveness.

Custom solutions

From prototyping to full-scale production, we tailor our services to your unique requirements, including material selection, tight tolerances, and specialized surface finishes.