A Comprehensive Guide to Plastic Injection Molding Services

- TN Plastics

- May 18, 2025

- 4 min read

Updated: May 29, 2025

If you’re an engineer, product developer, or sourcing specialist, understanding plastic injection molding services is key to making informed manufacturing decisions. This powerful process is the backbone of modern plastic part production—offering unmatched precision, speed, and scalability for industries ranging from medical and defense to automotive and industrial equipment.

At TN Plastics, a U.S.-based subsidiary of Tsubaki Nakashima Co., Ltd., we specialize in delivering high-performance, customized injection molding services—backed by ISO certification, engineering expertise, and a commitment to sustainability.

In this guide, you’ll learn how plastic injection molding works, its key benefits, applications, and how eco-friendly injection molding services are helping OEMs meet today’s environmental demands.

What Are Injection Molding Services?

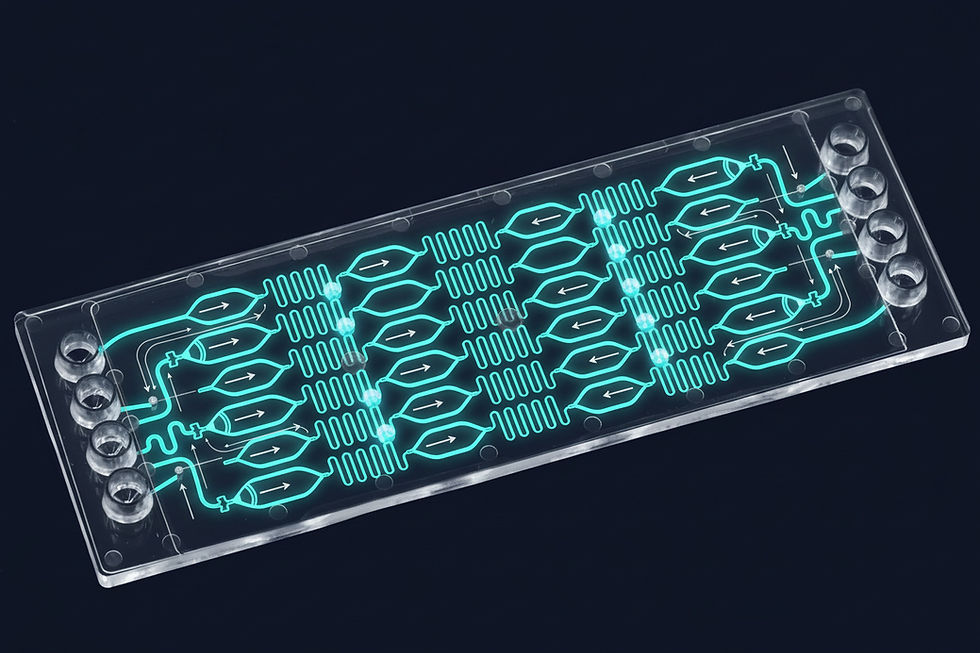

Injection molding services refer to the full suite of processes involved in producing plastic parts by injecting molten resin into a mold. Once cooled and solidified, the mold opens to release a finished part that often requires little or no post-processing.

The process includes:

· Tooling design and mold fabrication

· Material selection

· Injection molding production

· Post-processing (if needed)

· Quality assurance and certification

This method is ideal for high-volume production and is known for delivering consistent, durable parts with tight tolerances.

How the Injection Molding Process Works

The injection molding process follows four core steps:

Material Loading: Thermoplastic pellets are loaded into a hopper and heated in a barrel.

Injection: The melted plastic is injected into a steel or aluminum mold cavity under high pressure.

Cooling: The part is cooled inside the mold to harden and retain its shape.

Ejection: Once cooled, the mold opens and ejector pins release the finished component.

This cycle is fast and repeatable, making injection molding one of the most cost-effective manufacturing methods for plastic parts.

Why OEMs Choose Injection Molding Services

Here’s why manufacturers, engineers, and designers prefer injection molding over other methods:

Repeatable Precision

Consistent part quality with tight tolerances makes injection molding ideal for industries like medical devices, aerospace, and electronics.

Scalable Production

After tooling is complete, injection molding can produce thousands—or millions—of identical parts quickly and cost-effectively.

Design Flexibility

Molded parts can include complex geometries, internal threads, textured surfaces, and multiple materials.

Broad Material Selection

Choose from hundreds of thermoplastics, including FDA-grade, UV-resistant, flame-retardant, and chemical-resistant options.

Low Waste

Because parts are formed directly to shape, injection molding produces less scrap than many subtractive manufacturing methods.

Real-World Applications of Injection Molding Services

At TN Plastics, our injection molding solutions serve a wide range of industries:

Injection Molded Medical Devices

We manufacture parts used in medical housings, diagnostic tools, and laboratory equipment with precision and cleanroom-ready materials.

Defense and Aerospace

We supply high-spec, durable parts built to perform under pressure and in extreme conditions.

Industrial Equipment and Automation

We mold enclosures, mounts, seals, and fixtures that withstand heavy use and harsh environments.

Visit our Industries Served to see more use cases.

Eco-Friendly Injection Molding Services: Building Sustainably

As demand grows for sustainable manufacturing, TN Plastics is proud to offer eco-friendly injection molding services designed to reduce environmental impact without sacrificing performance.

Here’s how we deliver greener solutions:

Energy-Efficient Machinery: Our modern, automated injection molding equipment reduces power consumption and carbon output.

Waste Reduction: Our design-for-manufacturability process minimizes scrap, while optimized cycle times reduce excess material use.

Recycled Materials: Where possible, we offer parts using regrind or certified recycled resins.

We partner with clients who prioritize sustainability, helping them meet both their performance goals and ESG commitments.

Certifications That Back Up Our Quality

Certifications provide the foundation of trust in any injection molding partnership—especially when serving regulated industries.

TN Plastics is proudly ISO 13485:2016 and ISO-9001:2015 certified, which means our entire operation—from material sourcing to final inspection—is built around quality management systems that ensure:

· Full traceability

· Continuous improvement

· Risk-based thinking

· Reliable, repeatable results

We are also FDA registered, which allows us to manufacture components for injection molded medical devices and other applications that require FDA oversight.

If your application requires traceable and audit-ready production—especially for injection molded medical devices—we’ve got you covered.

When to Use Injection Molding Services

Injection molding services are best suited for projects that meet the following criteria:

High-volume production

Consistency and precision are essential

Complex shapes or tight tolerances are required

Material performance is critical

Lower per-part cost is a priority at scale

If you’re still in the early design stage, our engineering team can provide DFM guidance to ensure your part is mold-ready and cost-efficient.

Why Work with TN Plastics?

Choosing the right injection molding partner can make or break your product timeline. Here’s what sets TN Plastics apart:

U.S.-based production facility for faster lead times

In-house tooling, molding, and assembly

Global support through our parent company Tsubaki Nakashima

Commitment to eco-friendly practices

ISO 13485:2016 certification for quality assurance

We provide more than just parts—we offer the expertise and infrastructure to help your products succeed.

Contact Us Today to request a quote or schedule a project consultation.

Injection molding remains one of the most efficient and precise methods of manufacturing plastic parts at scale. Whether you’re developing a medical device, launching a new industrial product, or scaling your consumer brand, TN Plastics delivers the reliable injection molding services you need.

With certified quality systems, a focus on sustainability, and decades of manufacturing experience, we’re ready to help bring your next product to life.