Join TN-plastics at MD&M West 2026: Showcasing the Future of Medical Device Manufacturing

- TN Plastics

- Nov 6, 2025

- 3 min read

Updated: Nov 7, 2025

TN-plastics is excited to announce our participation in MD&M West 2026, North America's largest and most comprehensive medical device manufacturing event. Join us February 3-5, 2026 at the Anaheim Convention Center as we showcase our precision injection molding capabilities, FDA-registered cleanroom manufacturing, and innovative solutions serving the medical and diagnostic device industries. Visit our booth to discover how TN-plastics can accelerate your next medical device innovation.

About MD&M West 2026

MD&M West 2026 stands as the premier medical device manufacturing event on the West Coast, bringing together the entire product development ecosystem under one roof.

Event Details

Dates: February 3-5, 2026

Location: Anaheim Convention Center, 800 W Katella Ave, Anaheim, CA 92802

Expo Hours:

Tuesday, February 3: 10:00 AM – 5:00 PM

Wednesday, February 4: 10:00 AM – 5:00 PM

Thursday, February 5: 10:00 AM – 4:00 PM

Why MD&M West Matters for Medical Device Innovation

MD&M West 2026 represents an unparalleled opportunity for medical device professionals to explore innovations, source solutions, and connect with industry leaders.

Unmatched Scale and Industry Coverage

The 2026 event will feature:

Over 1,700 exhibitors showcasing the latest medical manufacturing technologies

14,000+ qualified trade visitors and decision-makers

Five integrated industry sectors: MedTech, Automation, Design & Manufacturing, Plastics, and Packaging

Comprehensive product coverage from concept through commercial production

Live product demonstrations and technology launches

Educational Programs and Networking Opportunities

Beyond the exhibit floor, MD&M West offers extensive learning and connection opportunities:

MedTech Conference covering design, compliance, cybersecurity, and manufacturing

SPE/MPD MiniTec Conference on medical plastics innovation

Sustainable Manufacturing Conference addressing efficiency and automation

Workshops on sterilization, AI, and smart manufacturing

Networking events connecting industry professionals

What You'll See at the TN-plastics Booth

Visit the TN-plastics booth to explore our comprehensive medical device manufacturing capabilities and discuss how we can support your next innovation.

Precision Injection Molding Expertise

Our booth will showcase:

FDA-registered Class 8 compliant cleanroom manufacturing

Precision molding for microfluidic devices and diagnostic components

Point-of-care device expertise in diabetes, cardiology, and molecular testing

Production scalability from prototype through 50 million pieces annually

ISO 13485:2016, ISO 9001, and ISO 14001 certifications

Complete validation services supporting regulatory submissions

Live Component Demonstrations

See examples of our manufacturing capabilities:

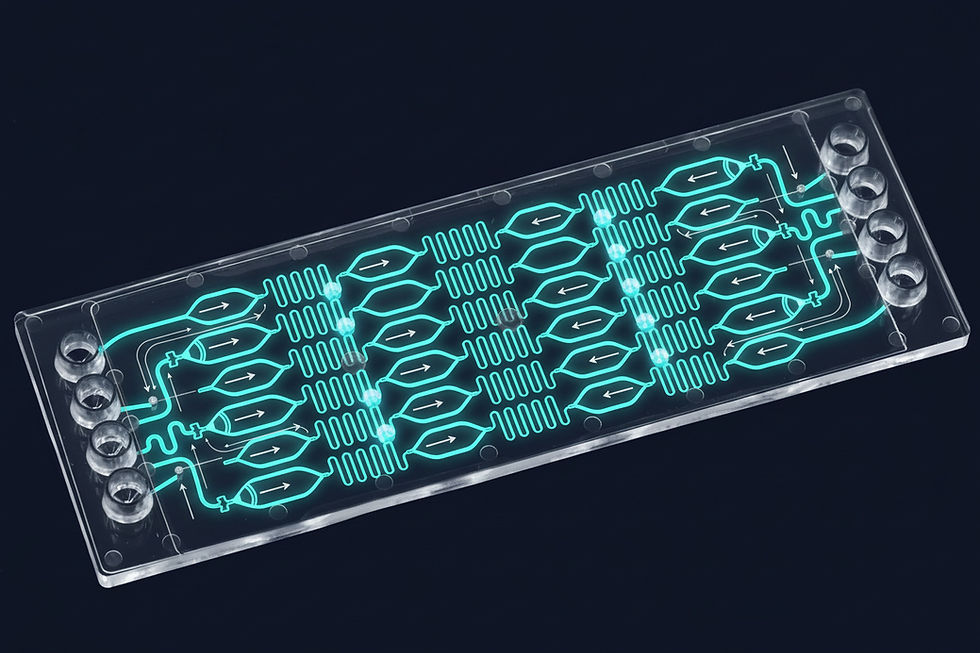

Microfluidic cartridges with sub-millimeter channel precision

Diagnostic test housings and sample collection components

Medical beads for assays and reagent handling

Laboratory consumables including tubes, dishes, and containers

Multi-material and overmolded assemblies

Engineering Support and Technical Consultation

Our engineering team will be available to discuss:

Design for Manufacturability (DFM) optimization

Material selection for biocompatibility and performance

Tooling strategies for rapid prototyping and production scaling

Process validation and regulatory documentation support

Cost optimization through design and manufacturing improvements

Why Partner with TN-plastics for Medical Device Manufacturing

TN-plastics brings over 100 years of manufacturing excellence combined with cutting-edge capabilities specifically designed for medical device applications.

Documented Competitive Advantages

Our proven capabilities include:

Over 100 billion parts shipped throughout company history

Recognized as top supplier to multiple diagnostic device manufacturers

Global Tsubaki Nakashima network providing supply chain security

Decades of partnership with leading medical OEMs

U.S.-based manufacturing ensuring proximity and compliance

Comprehensive support from concept through commercial production

Industry Trends and Future Technologies

Stop by our booth to discuss emerging trends shaping medical device manufacturing:

Microfluidics integration and lab-on-a-chip devices

Miniaturization and micro-molding requirements

AI and IoT connectivity in diagnostic platforms

Sustainable materials and eco-friendly manufacturing

Advanced polymers for enhanced biocompatibility

How to Connect with TN-plastics at MD&M West

We look forward to connecting with medical device innovators, engineers, and decision-makers at MD&M West 2026.

Visit Our MD&M West 2026 Booth

Booth Information: Visit us during expo hours February 3-5, 2026

Stop by for:

Live product demonstrations and component samples

One-on-one consultations with our engineering team

Technical discussions about your specific application needs

Information about our capabilities and certifications

Follow-up meeting scheduling for detailed project discussions

Pre-Schedule Your Meeting

To ensure dedicated time with our team, contact us in advance to schedule a booth meeting. This allows us to prepare for your specific needs and ensure the right technical experts are available.

Register for Free Admission

As an exhibitor, TN-plastics can provide complimentary expo passes to qualified attendees. Contact us for information about obtaining your free pass to MD&M West 2026.

Beyond the Booth: Making the Most of MD&M West

MD&M West 2026 represents the year's premier opportunity to discover innovations, source solutions, and connect with partners who can accelerate your medical device development. TN-plastics will be there to showcase how our precision injection molding expertise, FDA-registered cleanroom capabilities, and decades of medical device manufacturing experience can support your next breakthrough.

Mark your calendar for February 3-5, 2026, and plan to visit TN-plastics at the Anaheim Convention Center. We look forward to discussing how we can help transform your medical device concepts into commercial reality.