Precision Injection Molding for Point-of-Care Diagnostics: What Makes It Different?

- TN Plastics

- Sep 5, 2025

- 3 min read

The point-of-care (POC) diagnostics market is revolutionizing healthcare by bringing laboratory-quality testing directly to patients. As these devices become increasingly sophisticated and miniaturized, the precision injection molding processes that create their critical components face unique challenges that set them apart from traditional medical device manufacturing.

The Critical Role of Precision Injection Molding for Point-of-Care Diagnostics (POC) Device Manufacturing

Point-of-care diagnostic devices demand extraordinary precision that goes far beyond conventional medical device requirements. POC devices must deliver laboratory-accurate results in compact, portable formats while remaining cost-effective for widespread deployment.

Micron-Level Tolerance Requirements

The manufacturing tolerances for POC diagnostic components often operate at the micron level, with some features requiring precision within ±2-5 microns. This level of accuracy is essential for:

Microfluidic channels that guide precise sample volumes

Optical windows requiring perfect clarity and dimensional stability

Mixing chambers with exact volumetric specifications

Valve components ensuring leak-proof fluid control

TN-plastics' expertise in precision engineering, demonstrated through our Class 8 compliant cleanroom facilities and ISO 13485:2016 certification, positions us uniquely to meet these demanding specifications.

Medical-Grade Material Capabilities

As documented in our FDA registration (3014717638) and manufacturing capabilities, TN-plastics offers a comprehensive range of medical-grade materials specifically suited for POC diagnostic applications.

Biocompatible Material Portfolio

Our material selection capabilities include over 80 specific plastic formulations designed for medical applications, ensuring optimal performance for each unique application requirement.

Core Material Categories:

Medical-grade polypropylene (PP) for chemical resistance and sterilization compatibility

Polycarbonate (PC) for optical clarity and impact resistance

Polyethylene (PE) for flexible sealing and fluid handling components

ABS (Acrylonitrile Butadiene Styrene) for structural housings and dimensional stability

Thermoplastic elastomers (TPE/TPU) for gaskets and soft-touch applications

Quality and Compliance Standards

All materials meet stringent medical device requirements with full lot traceability from raw material to finished product. Our material sourcing utilizes a network of partnered resin manufacturers and distributors, ensuring consistent quality and availability.

USP Class VI biocompatibility certification available

ISO 10993 biological evaluation compliance where required

FDA compliant and 100% virgin materials available on request

Gamma, EtO, and steam sterilization compatibility testing

Material Selection Expertise

Our engineering team assists customer design engineers in product selection to determine optimal material, size, dimensional and surface characteristics for specific POC diagnostic applications. This collaborative approach ensures the selected materials meet both performance requirements and regulatory compliance needs.

Cleanroom Manufacturing Standards

The manufacturing of POC diagnostic components requires

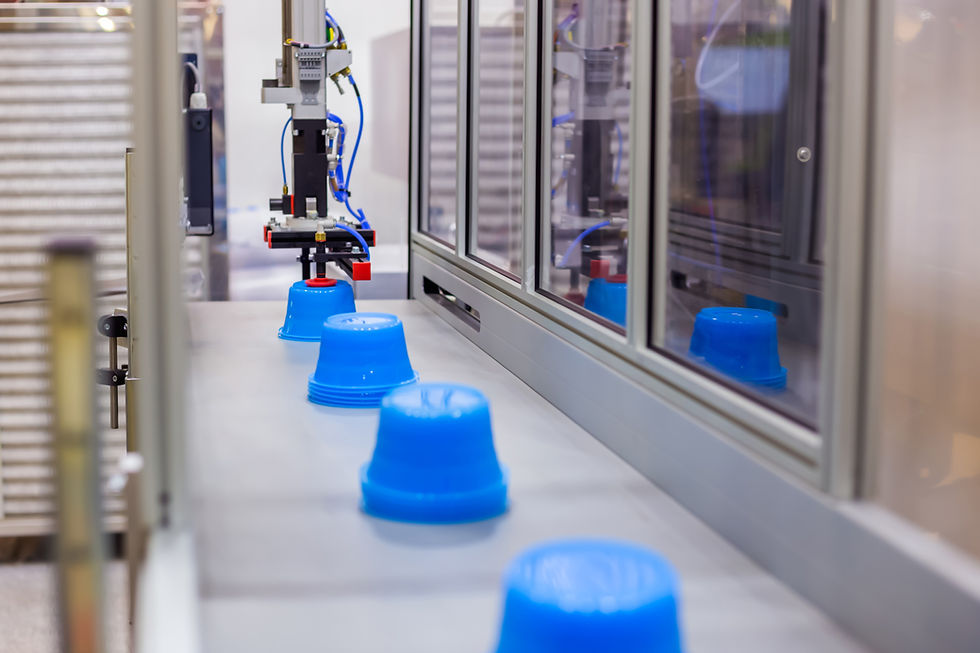

environments to prevent particle contamination. Our 22,000 sq. ft. facility with 8,000 sq. ft. Class 8 cleanroom maintains:

State-of-the-art injection molding and cleanroom technology

Advanced environmental controls and monitoring systems

Comprehensive personnel protocols and training programs

Controlled raw materials and finished goods storage areas

Complete Traceability

Every component includes comprehensive documentation with material lot traceability from raw material to finished product, process parameter recording, and quality control measurements throughout production.

Unique Manufacturing Challenges

The miniaturization of POC devices creates specific molding challenges that require specialized expertise:

Ultra-Precision Requirements:

Tight tolerances and special dimensional requirements for microfluidic applications

Special color, clarity, and light transmittance specifications

Lot-to-lot integrity for consistent diagnostic performance

Specialized Component Manufacturing:

Precision plastic tubes, cartridges, and diagnostic housings

Petri dishes and laboratory disposables for testing applications

Custom plastic beads for diagnostic, protein purification, and research applications

Advanced Quality Control Systems

Our ISO 13485:2016 certified quality management system ensures POC device components meet the highest standards through:

Stringent quality assurance systems and processes

Various incoming, in-process, and final inspections

Specialized testing methods and validation protocols

Zero defect quality vision and continuous improvement

Regulatory Compliance Excellence

As an FDA registered facility with comprehensive certifications, we ensure POC diagnostic components meet all regulatory requirements:

Certifications and Compliance:

FDA Registration Number 3014717638 for contract cleanroom injection molding

ISO 13485:2016 Medical Devices Quality Management certification

ISO 9001:2015 Quality Management System compliance

Class 8 compliant cleanroom operations with full environmental controls

Why Partner with TN-plastics for POC Manufacturing

We offer unique advantages for POC diagnostic device manufacturing:

Proven Heritage and Experience:

Established in 1913 as the first plastic ball manufacturer in the United States

Over 40 years of experience in precision plastic manufacturing for medical applications

Part of global Tsubaki Nakashima network with 90+ years of precision engineering expertise

Advanced Manufacturing Capabilities:

Class 8 compliant cleanroom with state-of-the-art injection molding equipment

Precision manufacturing with strict tolerances scalable to customer needs

Complete material traceability and lot control systems

Global Partnership and Recognition:

Recognized by top 10 medical OEMs worldwide for quality, delivery, and cost performance

Global network with local U.S. manufacturing and support

Trusted supplier with decades of medical industry relationships

At TN-plastics, we understand that precision injection molding for point-of-care diagnostics requires expertise that goes far beyond traditional manufacturing. Our combination of proven heritage, advanced cleanroom facilities, comprehensive material capabilities, and regulatory compliance ensures your POC devices meet the highest standards for accuracy, reliability, and performance.