Precision and Performance: Why U.S.-Based Custom Injection Molding Is Critical to Medical Device Success

- TN Plastics

- Aug 5, 2025

- 4 min read

As the global healthcare industry advances rapidly, medical and diagnostic device manufacturers face increasing pressure to deliver precise, scalable, and compliant solutions — all while controlling costs and shortening development timelines. In this environment, injection molded medical devices have emerged as the gold standard for producing high-volume, high-performance plastic components that meet the stringent demands of modern medicine.

For companies looking to compete and lead in this space, finding the right injection molding services partner is essential — and that often starts with custom mold design, domestic production, and a partner that can facilitate easy mold transfers without compromising quality.

Here’s how the right strategy and supplier can make all the difference in medical injection molding.

The Expanding Role of Injection Molded Medical Devices

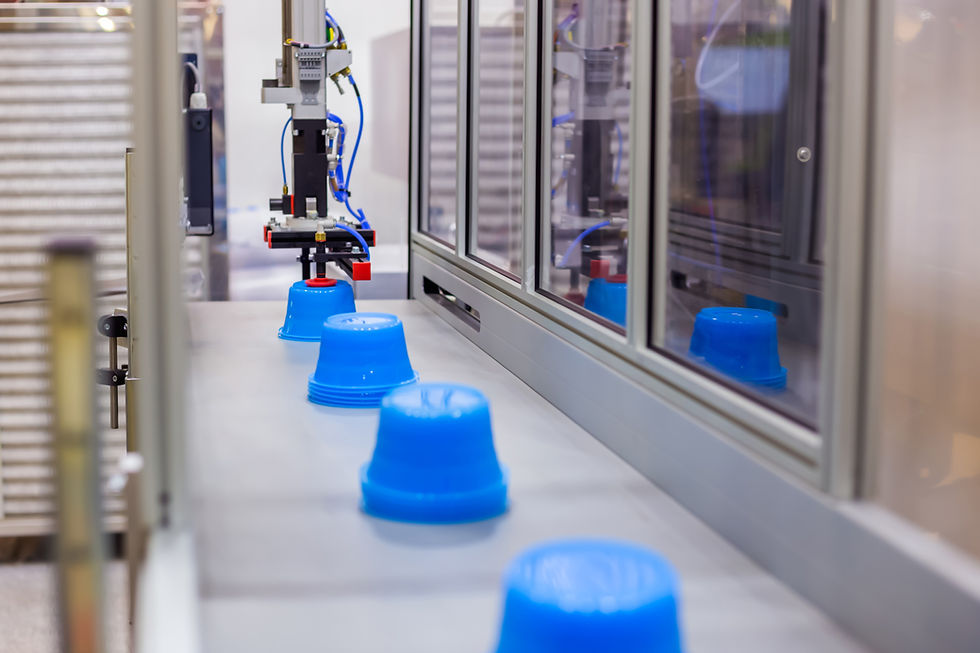

From hospitals to diagnostic labs, injection molded components are everywhere in modern healthcare. Their prevalence is largely due to the manufacturing process’s ability to produce complex parts with extreme precision and consistency at scale.

Common injection molded medical devices and components include:

Diagnostic housings and cartridges

Drug delivery systems

Fluid handling components

Surgical instrument parts

Medical packaging and closures

Reagent mixing beads and transport media components

In regulated environments where precision, cleanliness, and repeatability are critical, injection molding offers a high level of control over material performance, dimensional accuracy, and part consistency — making it ideal for single-use devices, wearable tech, and complex consumables.

Why U.S.-Based Custom Injection Molding Services Matter

Global supply chains have never been more unpredictable. Lead times, shipping costs, and regulatory concerns are now top-of-mind for medical device manufacturers seeking greater control and lower risk.

This is why U.S.-based custom injection molding services are gaining attention — not just for proximity, but for quality assurance, reliability, and speed.

At TN Plastics, we operate a U.S.-based manufacturing facility in Michigan that serves some of the most advanced healthcare and diagnostics applications on the market. Our in-house capabilities allow us to meet tight delivery windows, respond quickly to design iterations, and maintain strong quality control — without the disruptions often associated with overseas sourcing.

Advantages of domestic molding include:

Faster turnaround on tooling and production

Streamlined communication with local teams

No international shipping delays or tariffs

Greater transparency and accountability

Choosing a U.S.-based partner also supports FDA registration, ISO 13485 compliance, and consistent traceability — all critical in regulated medical applications.

Custom Mold Design: Engineering for Functionality and Scalability

One of the most important aspects of a successful injection molding project is custom mold design. The mold is the foundation of your product’s performance, and any flaw in its construction can lead to costly delays, nonconformities, or part failure in the field.

Custom mold design involves far more than replicating a 3D CAD model. It requires deep expertise in tooling, part geometry, material behavior, and process optimization.

At TN Plastics, our team brings years of experience in custom tool development for high-precision plastic components. We partner closely with customers to ensure every mold we produce or inherit supports long-term performance and consistent yield.

Our design and toolmaking support includes:

Multi-cavity and high-volume mold builds

Tool validation and qualification

Engineering support for Design for Manufacturability (DFM)

Integration with fully automated production and inspection systems

Whether you’re launching a new product or scaling an existing line, expert mold design ensures repeatable results and lower long-term costs.

Smooth Mold Transfers: How TN Plastics Simplifies the Switch

Many manufacturers hesitate to move tooling from one supplier to another — even when quality or service is an issue. But with the right partner, mold transfers can be simple, efficient, and even beneficial to your bottom line.

At TN Plastics, we specialize in easy mold transfers, making it possible to switch production with minimal downtime. Whether your current molder is located overseas, experiencing capacity issues, or lacking the compliance infrastructure needed for medical applications, our experienced team will guide you through every step of the transition.

Our mold transfer services include:

In-depth tool evaluations

Validation runs and part comparisons

Mold refurbishing or modification (if needed)

Seamless integration into our cleanroom production environment

We understand that medical production cannot afford delays or defects — and our robust quality and inspection processes ensure a smooth ramp-up without sacrificing consistency.

Cleanroom Manufacturing & Regulatory Readiness

Injection molding for medical applications requires more than just precision. It demands strict environmental control and full compliance with regulatory expectations.

At TN Plastics, we manufacture many of our components in an ISO Class 8 cleanroom, helping to ensure parts are produced in a controlled, contaminant-free environment. This is especially critical for components used in point-of-care testing, diagnostics, and fluid management — where contamination risks can compromise results or patient safety.

Additionally, our processes follow ISO 13485 quality management standards, which are essential for medical device manufacturing and regulatory compliance. Our integrated inspection systems and traceable production workflows support customer audits, validations, and product registrations with ease.

Materials for Medical Injection Molding

Material selection is another vital piece of the puzzle. Medical-grade plastics must be biocompatible, chemically resistant, and often able to withstand sterilization processes (gamma, EtO, steam autoclaving).

Common materials used in injection molded medical devices include:

Polypropylene (PP)

Polycarbonate (PC)

Polyethylene (PE)

ABS (Acrylonitrile Butadiene Styrene)

Thermoplastic elastomers (TPE/TPU)

Selecting the right resin depends on the application, exposure environment, and regulatory requirements. An experienced molder like TN Plastics can help you match materials to performance needs, ensuring optimal results in real-world clinical settings.

Backed by a Global Precision Leader

As a subsidiary of Tsubaki Nakashima, a global manufacturer of high-precision components, TN Plastics combines local agility with international expertise. This allows us to support complex projects with the scale, support, and stability that medical customers require.

Our unique position gives clients access to high-quality manufacturing without the red tape of large contract manufacturers — and with the responsiveness and care of a specialized partner.

Powering the Future of Medical Devices with Smart Injection Molding

As innovation accelerates in healthcare and diagnostics, injection molded medical devices are helping companies deliver smarter, safer, and more scalable solutions. But the success of these components depends on precision design, quality execution, and reliable partnerships.

At TN Plastics, we provide custom mold design, U.S.-based injection molding services, and easy mold transfers that empower our clients to move faster, reduce risk, and focus on innovation.

Looking for a trusted injection molding partner for your next medical device or diagnostic application?

Contact TN Plastics today to explore how we can support your program.