The Role of Injection Molded Components in Rapid Diagnostic Testing

- TN Plastics

- Dec 4, 2025

- 4 min read

The Role of Injection Molded Components in Rapid Diagnostic Testing

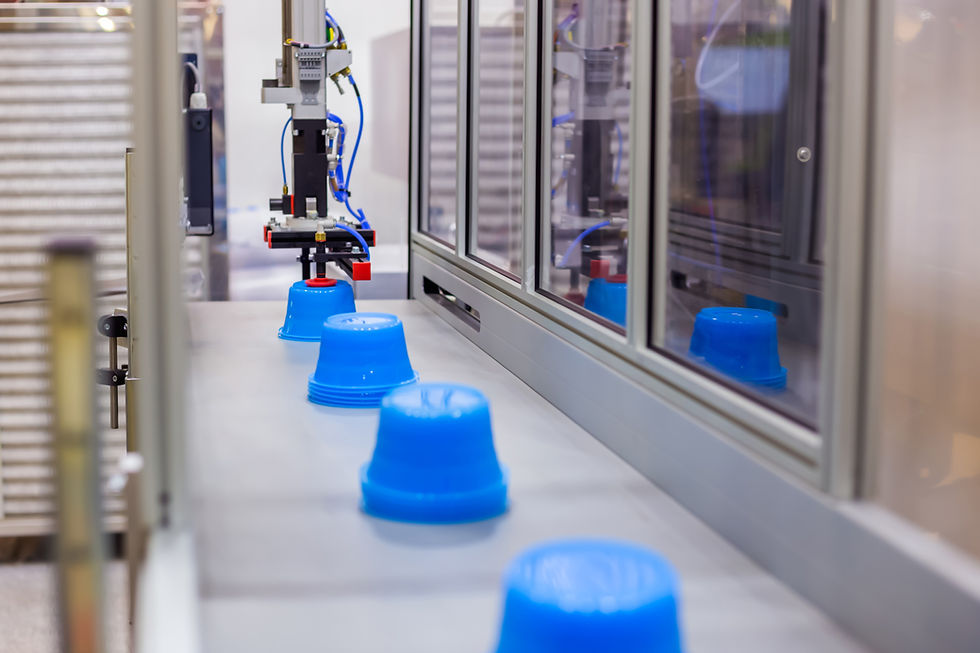

Rapid diagnostic testing has revolutionized healthcare by enabling quick, accurate disease detection at the point of care. Behind every reliable test lies precision-engineered plastic components that make rapid diagnostics possible. At TN-plastics, our expertise in medical device injection molding supports the effectiveness of rapid tests through components that combine dimensional accuracy, material performance, and manufacturing consistency—three essential factors that determine diagnostic reliability.

The Critical Role of Injection Molded Components in Rapid Diagnostic Testing

Rapid diagnostic tests rely on precise fluid handling, consistent geometry, and biocompatible materials to deliver accurate results. Injection molded plastic components serve as the foundation for these critical performance requirements.

Injection molded components perform essential functions in diagnostic testing:

Sample collection and containment ensuring proper volumes and preventing contamination

Microfluidic channels directing precise fluid flow for consistent test reactions

Reagent chambers maintaining separation until testing while enabling controlled mixing

Optical windows providing clear visualization for result interpretation

Structural housings protecting sensitive test strips and reaction zones

Precision Requirements: How Accuracy Drives Diagnostic Performance

The effectiveness of rapid diagnostic tests depends fundamentally on dimensional precision and consistency of molded components. Even minor variations can compromise test accuracy and reliability.

Critical Dimensional Tolerances

Diagnostic components require exceptionally tight tolerances to function properly:

Microfluidic channels: Sub-millimeter precision (often ≤ 0.1mm) for consistent fluid flow

Sample wells: Volume accuracy within ±2-5% to ensure proper sample-to-reagent ratios

Optical surfaces: Surface finish requirements measuring Ra < 0.1µm for clear visualization

Mating features: Tolerance control to ±0.05mm or tighter for leak-free assembly

Wall thickness: Uniformity within ±5% preventing optical distortion and ensuring structural integrity

At TN-plastics, our Class 8 compliant cleanroom and advanced injection molding technology enable us to consistently achieve these demanding tolerances across high-volume production.

Material Performance: Enabling Test Reliability

Material selection critically impacts diagnostic test performance. Injection molded components must meet multiple requirements simultaneously:

Chemical Compatibility and Resistance

Diagnostic test components contact various biological samples and chemical reagents:

Resistance to buffers, acids, and bases used in diagnostic assays

Non-reactivity with biological samples (blood, saliva, urine) preventing test interference

Stability during storage preventing material degradation over product shelf life

Compatibility with sterilization methods (gamma radiation, EtO, autoclave)

Low extractables meeting regulatory requirements for patient sample contact

Optical Clarity for Result Visualization

Many diagnostic tests rely on visual or optical detection systems requiring:

High light transmittance (>90%) for spectrophotometric detection

Low haze and minimal optical distortion for accurate color interpretation

Consistent optical properties across production batches

UV stability preventing yellowing or degradation affecting results

Appropriate refractive index for lens or waveguide applications

Manufacturing Consistency: The Foundation of Test Reliability

Diagnostic test manufacturers depend on part-to-part consistency across millions of units to ensure reliable test performance.

Advanced Process Control for Consistent Quality

TN-plastics employs comprehensive process controls ensuring consistency:

Statistical Process Control (SPC) monitoring critical parameters in real-time

Scientific molding methodology establishing robust process windows

Automated inspection systems providing 100% dimensional verification

Environmental controls maintaining cleanroom conditions (Class 6-8 compliance)

Complete lot traceability from raw materials through finished components

Validation Supporting Regulatory Requirements

Our ISO 13485:2016 certified quality management system provides comprehensive validation support:

Installation Qualification (IQ) verifying equipment and facility readiness

Operational Qualification (OQ) establishing optimal processing parameters

Performance Qualification (PQ) demonstrating consistent production capability

Material certification and biocompatibility documentation

Process validation protocols meeting FDA and international requirements

Injection Molded Components in Diagnostic Applications

TN-plastics manufactures components supporting diverse rapid diagnostic applications with documented expertise in multiple testing platforms.

Point-of-Care Diagnostic Devices

Our components support various point-of-care applications including:

Diabetes monitoring devices requiring precise sample chambers and optical windows

Cardiology testing cartridges with integrated microfluidic channels

Blood management systems featuring complex fluid handling components

Infectious disease lateral flow housings protecting test strips and providing result windows

Laboratory Diagnostic Consumables

High-volume laboratory testing relies on our precision components:

PCR testing plates and tubes requiring thermal stability and uniform wall thickness

Amino assay cartridges with precise well volumes and surface treatments

Sample tubes and containers providing reliable sealing and chemical resistance

Microplates featuring consistent well geometry and optical clarity

Design Collaboration: Optimizing Components for Manufacturing

Successful diagnostic device development requires early manufacturing engagement to optimize designs for both performance and producibility.

Design for Manufacturability (DFM) Analysis

Our engineering team provides comprehensive DFM support:

Flow analysis simulation predicting fill patterns and identifying potential defects

Wall thickness optimization balancing structural integrity with moldability

Gate location analysis ensuring complete filling while minimizing cosmetic impact

Tolerance stack-up analysis preventing assembly issues

Material selection guidance matching performance requirements with processing characteristics

Seamless Transition from Prototyping to Production

TN-plastics supports the complete development cycle:

Rapid prototyping enabling early design validation

Progressive tooling strategies balancing speed and production readiness

Process development concurrent with design iteration

Scalability from low-volume validation to high-volume production

Production capacity supporting 1 million to 50 million pieces annually

TN-plastics: Proven Expertise in Diagnostic Component Manufacturing

Our comprehensive capabilities support diagnostic device manufacturers with validated expertise and documented performance.

Documented Manufacturing Capabilities

TN-plastics delivers measurable value through:

Over 100 billion parts shipped throughout company history

Recognition as top supplier to multiple diagnostic suppliers

FDA-registered facility with Class 8 cleanroom capability

ISO 13485:2016, ISO 9001, and ISO 14001 certifications

Production capacity: 1-50 million injection molded pieces annually

Complete validation services including IQ/OQ/PQ protocols

Global Tsubaki Nakashima network providing supply chain security

Quality and Regulatory Commitment

Our quality management approach ensures diagnostic component excellence:

Statistical process capability studies (Cpk ≥ 1.33) for critical dimensions

Automated inspection systems ensuring consistent quality

Environmental monitoring and cleanroom qualification

Material traceability supporting regulatory submissions

Continuous process verification maintaining validated state

Rapid diagnostic testing demands precision, consistency, and reliability from every component. At TN-plastics, our expertise in medical device injection molding delivers the dimensional accuracy, material performance, and manufacturing consistency that make effective diagnostic testing possible. From microfluidic channels to complete cartridge housings, our components contribute to faster, more accurate diagnoses that improve patient outcomes.

When your diagnostic innovation requires components that meet the most demanding performance and regulatory requirements, trust TN-plastics to deliver injection molding excellence backed by over a century of manufacturing expertise and proven results in medical device manufacturing.